Dec 24, 2020

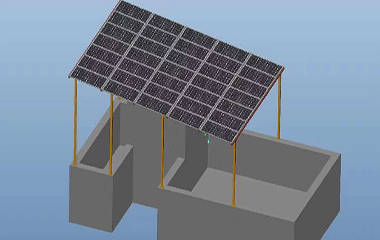

Reasons to Buy Solar Rooftop Power System

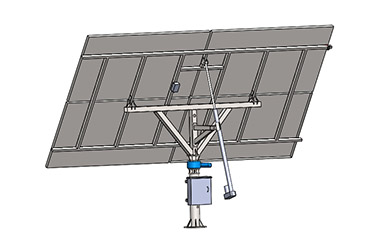

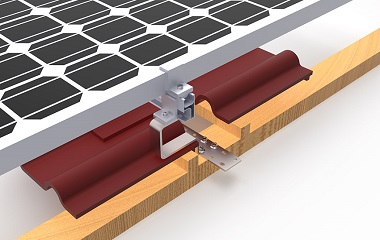

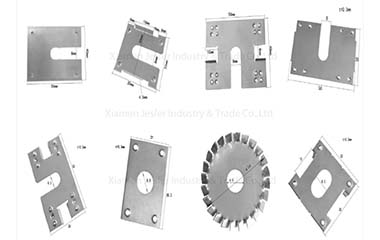

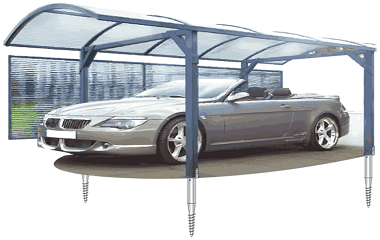

In the industrial park, the roof of the science and technology park, schools, hospitals, hotels, etc., are the best places to install solar roof system plant projects. Not only the industrial and commercial roof area is large, but also the electricity consumption and electricity price is high, There are four main reasons to buy rooftop photovoltaic energy system for industrial and commercial use as follows! 1. Stabilize cash flow and increase corporate income If you want to install photovoltaic power generation on these roofs, you can revitalize the fixed assets of the company, increase a stable cash flow, and make the company's income better. Enterprises consume large amounts of electricity and have high front-end electricity bills. After photovoltaic power generation is installed, enterprises can use them spontaneously and use surplus electricity on the Internet. 2. Saving peak electricity bills and sell surplus electricity online Especially for high-energy-consuming production enterprises, installing solar plant system can save a lot of electricity expenses, which not only saves money, but also makes money. For production companies that are striving for division, the yield of photovoltaic power generation is much higher than that of many traditional production companies, and it is very worthy of investment. 3. Promote energy saving and emission reduction, and produce good social benefits Every local government will issue energy-saving and emission-reduction targets to productive enterprises. Some high-energy-consuming enterprises cannot complete them and can only accept high fines. The installation of solar system power plant stations can achieve energy conservation and emission reduction. There is no geographical restriction. You only need to install a set of photovoltaic roof power systems on the restricted roof to achieve energy conservation and emission reduction goals. With many advantages such as no noise, no radiation, no emissions, no pollution, photovoltaic power generation has become a must-choice configuration for medium and large enterprises. 4. Heat insulation and cold protection, increase environmental comfort Many production enterprises have colored steel tile roofs or small flat floors, which require high cooling costs in the hot summer. Photovoltaic panels have the function of heat insulation. After photovoltaic modules are placed on the roof, the temperature of the downstairs workshop can be effectively reduced. It can make the workers downstairs work more comfortable, and the production equipment can run smoothly, which indirectly reduces the cooling costs of air conditioners, fans and ice cubes. Xiamen Jesfer Industry & Trade Co.,ltd., can provide complete solar power system with high quality product ,either on grid pv system or off grid solar system ,we are keeping on reseach & development our technology to adapt new trend and tide .

View More